Geotechnical Drilling and Engineering

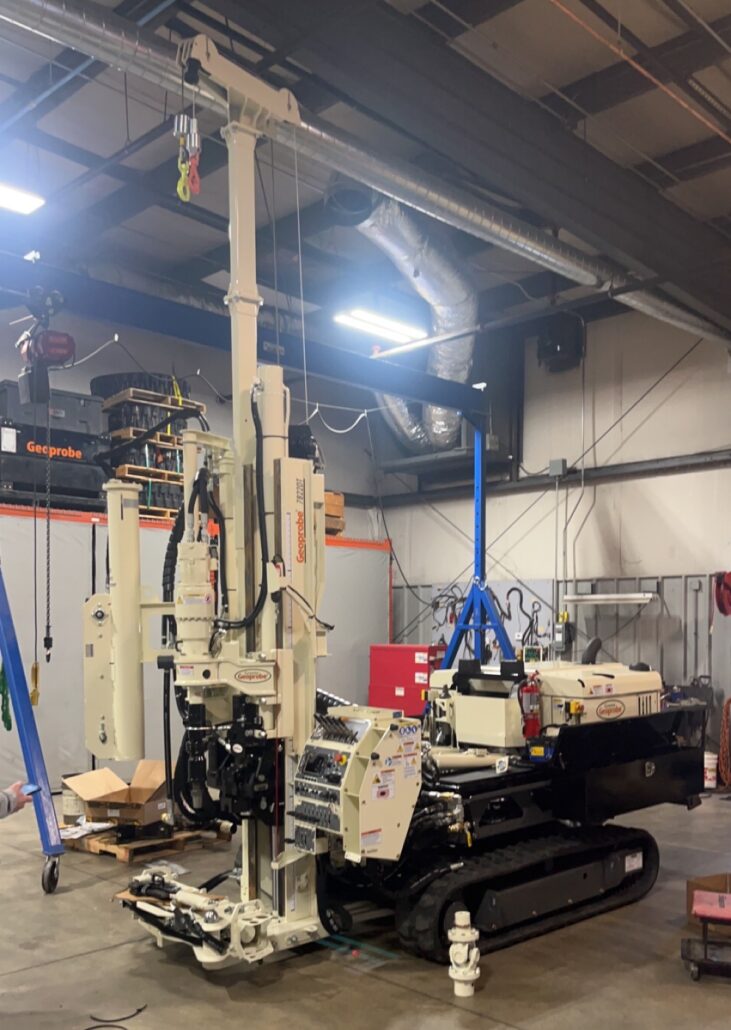

Twin Ports Testing’s experienced team of Geotechnical Engineers, drillers, and engineering technicians perform geotechnical drilling and evaluations to gain information on the properties of the soil, groundwater, and rock that sits beneath proposed structures. We utilize a fleet of Geoprobe Systems drill rigs.

These geotechnical evaluations include subsurface explorations of the site, where the drilling team will perform soil borings, subsurface sampling, and laboratory testing of the soil samples retrieved. This is crucial to determine the physical, mechanical, and chemical properties that will play a factor in the project under consideration, and aids in assessing any potential risks that may be created by the site conditions. After evaluation, the engineering team will use all of the information to provide recommendations that will allow the project to proceed in a safe and successful way.

Geotechnical Drilling – Hollow Stem Auger, Mud Rotary, Bedrock Coring

- Hollow Stem Auger Inner Diameters: 2 ¼”, 3 ¼”, 4 ¼”, 6 ¼”

- Mud Rotary: 2 15/16” through 5 7/8”

- Bedrock Coring: NQ wireline and HV conventional size cores along with HWT casing system

In Situ Testing – CPTu, DMT, Seismic CPTu

- Flat Plate Dilatometer: The flat plate dilatometer (DMT) is an efficient, accurate, and time-proven soil testing method to determine a variety of geotechnical parameters. This method is commonly implemented in shallow foundation and pile design. The dilatometer consists of a steel blade that is pushed into the ground. A flat, circular, stainless steel membrane located on the face of the blade connects to a control box at the surface. The membrane is inflated against the soil at regular intervals and the pressure measured. One of the major advantages of dilatometry is its capability to be combined with other test methods during drilling.

- Cone Penetration Testing: We perform cone penetration testing (CPTu) using a self-anchoring rubber track-mounted Geoprobe Systems 6625CPT rig. CPTu measures tip resistance, side friction, and pore water pressure in 2 cm intervals throughout the depth of the push to depths beyond 150 feet. In addition, we have the capability to measure Seismic S-waves at selected intervals during the sounding. Physical soil samples can be collected in an adjacent borehole using direct push or standard geotechnical drilling techniques with the same drill rig.

Environmental Drilling, Direct Push Sampling, and Monitoring Well Installations

- Phase 2 Environmental Site Assessment

- Temporary and permanent monitoring well installations and abandonment

- Groundwater sampling

Geotechnical instrumentation installation

- Inclinometer Casing

- Vibrating wire and open pipe piezometers

- Extensometers

- Settlement Plates

Geotechnical Engineering

- Commercial Buildings

- Bridges/Culverts

- Cell Phone Towers

- Slope Stability

- Roads and pavement design

Our Drill Rig Fleet

Please contact our Geotechnical Team Lead to request our services or additional information.

Jim Johnson, PE

Vice President/Geotechnical Engineer